#Ethylene Carbonate News

Explore tagged Tumblr posts

Text

Ethylene Carbonate Price | Prices | Pricing | News | Database | Chart

Ethylene Carbonate is a chemical compound widely used in industries such as electronics, automotive, and energy storage. It is a colorless, odorless, and highly polar solvent, making it crucial in applications like lithium-ion batteries, surface coatings, and as an intermediate in the production of other chemicals. In recent years, the price of ethylene carbonate has become a topic of considerable interest for manufacturers and investors alike. Several factors influence ethylene carbonate prices, including raw material costs, demand from key industries, geopolitical events, and changes in environmental regulations.

One of the primary determinants of ethylene carbonate prices is the cost of raw materials, particularly ethylene oxide. Ethylene oxide is derived from ethylene, a byproduct of crude oil and natural gas refining. Consequently, fluctuations in crude oil prices have a direct impact on ethylene oxide production costs, which in turn affects ethylene carbonate prices. When crude oil prices rise, the cost of producing ethylene oxide also increases, leading to higher prices for ethylene carbonate. On the other hand, when crude oil prices fall, manufacturers benefit from lower raw material costs, which can help stabilize or reduce the price of ethylene carbonate.

Get Real Time Prices for Ethylene Carbonate: https://www.chemanalyst.com/Pricing-data/ethylene-carbonate-ec-1193

Demand from key industries, particularly the battery and automotive sectors, plays a critical role in determining ethylene carbonate prices. With the rapid growth of electric vehicles (EVs), the demand for lithium-ion batteries has surged. Since ethylene carbonate is a key electrolyte solvent in lithium-ion batteries, the rising demand for EVs has led to increased consumption of ethylene carbonate. As the EV market continues to expand, especially in regions like China, Europe, and North America, the demand for ethylene carbonate is expected to rise further, exerting upward pressure on prices.

Another factor that impacts ethylene carbonate prices is the availability of production capacity. The global production of ethylene carbonate is concentrated in a few key regions, such as Asia, particularly China and South Korea, which are major producers and consumers of ethylene carbonate. Any disruptions in the supply chain, such as plant shutdowns or production curtailments due to maintenance, natural disasters, or geopolitical issues, can lead to shortages, driving up prices. Additionally, new capacity additions or expansions by manufacturers can help alleviate supply constraints and stabilize prices over time.

Environmental regulations also have a significant influence on ethylene carbonate prices. As governments around the world implement stricter environmental policies to reduce greenhouse gas emissions and promote sustainable energy sources, industries that rely on fossil fuels, including those involved in ethylene carbonate production, face increased costs. Compliance with environmental regulations may require investments in cleaner technologies or the adoption of more sustainable production practices, which can drive up production costs and, in turn, ethylene carbonate prices. Moreover, the growing emphasis on recycling and the development of eco-friendly alternatives could affect future demand patterns and influence price trends.

Geopolitical factors, such as trade tensions, tariffs, and sanctions, also contribute to fluctuations in ethylene carbonate prices. For instance, trade disputes between major economies like the United States and China can disrupt the global supply chain for chemicals, including ethylene carbonate, leading to price volatility. In some cases, tariffs on imported raw materials or finished products may increase the cost of production, further pushing up prices. Conversely, improved diplomatic relations and trade agreements between countries could facilitate smoother trade flows, potentially leading to more stable ethylene carbonate prices.

In addition to these external factors, technological advancements in the manufacturing processes of ethylene carbonate also play a role in influencing prices. Innovations that improve production efficiency, reduce waste, or lower energy consumption can help manufacturers reduce their operating costs, which may lead to more competitive pricing. Furthermore, advancements in alternative materials or electrolyte formulations for batteries could impact the long-term demand for ethylene carbonate, potentially leading to changes in its price structure.

The global ethylene carbonate market is also shaped by macroeconomic conditions, such as inflation, currency fluctuations, and overall economic growth. During periods of economic expansion, industrial activity tends to increase, boosting demand for chemicals like ethylene carbonate. Conversely, economic slowdowns or recessions can lead to reduced industrial activity and lower demand, putting downward pressure on prices. Additionally, inflationary pressures can increase the cost of raw materials, labor, and transportation, all of which contribute to higher production costs and elevated ethylene carbonate prices.

Looking ahead, the future of ethylene carbonate prices will likely be influenced by the ongoing transition toward renewable energy and the electrification of the automotive industry. As the demand for electric vehicles continues to grow, the need for high-performance lithium-ion batteries will remain strong, driving demand for ethylene carbonate. However, the development of new battery technologies, such as solid-state batteries, which may require different electrolytes, could potentially impact the long-term demand for ethylene carbonate. Moreover, efforts to reduce reliance on fossil fuels and adopt more sustainable production methods may result in both opportunities and challenges for ethylene carbonate manufacturers.

In conclusion, ethylene carbonate prices are influenced by a complex interplay of factors, including raw material costs, demand from key industries, environmental regulations, geopolitical events, and technological advancements. While the growing demand for electric vehicles and lithium-ion batteries is expected to support the long-term demand for ethylene carbonate, price volatility will likely persist due to supply chain disruptions, fluctuating raw material prices, and evolving market dynamics. As industries and policymakers continue to focus on sustainability and innovation, the future of ethylene carbonate prices will depend on how these factors evolve in the coming years.

Get Real Time Prices for Ethylene Carbonate: https://www.chemanalyst.com/Pricing-data/ethylene-carbonate-ec-1193

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Ethylene Carbonate#Ethylene Carbonate Price#Ethylene Carbonate Prices#Ethylene Carbonate Pricing#Ethylene Carbonate News

0 notes

Text

"The sleeping giant of the US Environmental Protection Agency (EPA) has stirred.

In the past month, an avalanche of anti-pollution rules, targeting everything from toxic drinking water to planet-heating gases in the atmosphere, have been issued by the agency. Belatedly, the sizable weight of the US federal government is being thrown at longstanding environmental crises, including the climate emergency.

On Thursday [May 18, 2023], the EPA’s month of frenzied activity was crowned by the toughest ever limits upon carbon pollution from America’s power sector, with large, existing coal and gas plants told they must slash their emissions by 90% or face being shut down.

The measure will, the EPA says, wipe out more than 600m tons of carbon emissions over the next two decades, about double what the entire UK emits each year. But even this wasn’t the biggest pollution reduction announced in recent weeks.

In April, new emissions standards for cars and trucks will eliminate an expected 9bn tons of CO2 by the mid-point of the century, while separate rules issued late last year aim to slash hydrofluorocarbons, planet-heating gases used widely in refrigeration and air conditioning, by 4.6bn tons in the same timeframe. Methane, another highly potent greenhouse gas, will be curtailed by 810m tons over the next decade in another EPA edict.

In just a few short months the EPA, diminished and demoralized under Donald Trump, has flexed its regulatory muscles to the extent that 15bn tons of greenhouse gases – equivalent to about three times the US’s carbon pollution, or nearly half of the entire world’s annual fossil fuel emissions – are set to be prevented, transforming the power basis of Americans’ cars and homes in the process...

If last year’s Inflation Reduction Act (IRA), with its $370bn in clean energy subsidies and enticements for electric car buyers, was the carrot to reducing emissions, the EPA now appears to be bringing a hefty stick.

The IRA should help reduce US emissions by about 40% this decade but the cut needs to be deeper, up to half of 2005 levels, to give the world a chance of avoiding catastrophic heatwaves, wildfires, drought and other climate calamities. The new rules suddenly put America, after years of delay and political rancor, tantalizingly within reach of this...

“It’s clear we’ve reached a pivotal point in human history and it’s on all of us to act right now to protect our future,” said Michael Regan, the administrator of the EPA, in a speech last week at the University of Maryland. The venue was chosen in a nod to the young, climate-concerned voters Joe Biden hopes to court in next year’s presidential election, and who have been dismayed by Biden’s acquiescence to large-scale oil and gas drilling.

“Folks, this is our future we are talking about, and we have a once-in-a-generation opportunity for real climate action,” [Michael Regan, the administrator of the EPA], added. “Failure is not an option, indifference is not an option, inaction is not an option.” ...

It’s not just climate the EPA has acted upon in recent months. There are new standards for chemical plants, such as those that blight the so-called "Cancer Alley" the US, from emitting cancer-causing toxins such as benzene, ethylene oxide and vinyl chloride. New rules curbing mercury, arsenic and lead from industrial facilities have been released, as have tighter limits on emissions of soot and the first ever regulations targeting the presence of per- and polyfluoroalkylsubstances (or PFAS) in drinking water.” ...

For those inside the agency, the breakneck pace has been enervating. “It’s definitely a race against time,” said one senior EPA official, who asked not to be named. “The clock is ticking. It is a sprint through a marathon and it is exhausting.” ...

“We know the work to confront the climate crisis doesn’t stop at strong carbon pollution standards,” said Ben Jealous, the executive director of the Sierra Club.

“The continued use or expansion of fossil power plants is incompatible with a livable future. Simply put, we must not merely limit the use of fossil fuel electricity – we must end it entirely.”"

-via The Guardian (US), 5/16/23

#epa#environmental protection agency#united states#us politics#coal#cw cancer mention#pfas#sustainability#carbon emissions#good news#hope

6K notes

·

View notes

Text

Our planet is choking on plastics. Some of the worst offenders, which can take decades to degrade in landfills, are polypropylene—which is used for things such as food packaging and bumpers—and polyethylene, found in plastic bags, bottles, toys, and even mulch.

Polypropylene and polyethylene can be recycled, but the process can be difficult and often produces large quantities of the greenhouse gas methane. They are both polyolefins, which are the products of polymerizing ethylene and propylene, raw materials that are mainly derived from fossil fuels. The bonds of polyolefins are also notoriously hard to break.

Now, researchers at UC Berkeley have come up with a method of recycling these polymers that uses catalysts that easily break their bonds, converting them into propylene and isobutylene, which are gases at room temperature. Those gases can then be recycled into new plastics.

“Because polypropylene and polyethylene are among the most difficult and expensive plastics to separate from each other in a mixed waste stream, it is crucial that [a recycling] process apply to both polyolefins,” the research team said in a study recently published in Science.

Breaking It Down

The recycling process the team used is known as isomerizing ethenolysis, which relies on a catalyst to break down olefin polymer chains into their small molecules. Polyethylene and polypropylene bonds are highly resistant to chemical reactions, because both of these polyolefins have long chains of single carbon-carbon bonds. Most polymers have at least one carbon-carbon double bond, which is much easier to break.

While isomerizing ethenolysis had been tried by the same researchers before, the previous catalysts were expensive metals that did not remain pure long enough to convert all of the plastic into gas. Using sodium on alumina followed by tungsten oxide on silica proved much more economical and effective, even though the high temperatures required for the reaction added a bit to the cost.

In both plastics, exposure to sodium on alumina broke each polymer chain into shorter polymer chains and created breakable carbon-carbon double bonds at the ends. The chains continued to break over and over. Both then underwent a second process known as olefin metathesis. They were exposed to a stream of ethylene gas flowing into a reaction chamber while being introduced to tungsten oxide on silica, which resulted in the breakage of the carbon-carbon bonds.

The reaction breaks all the carbon-carbon bonds in polyethylene and polypropylene, with the carbon atoms released during the breaking of these bonds ending up attached to molecules of ethylene. “The ethylene is critical to this reaction, as it is a coreactant,” researcher R.J. Conk, one of the authors of the study, told Ars Technica. “The broken links then react with ethylene, which removes the links from the chain. Without ethylene, the reaction cannot occur.”

The entire chain is catalyzed until polyethylene is fully converted to propylene, and polypropylene is converted to a mixture of propylene and isobutylene.

This method has high selectivity—meaning it produces a large amount of the desired product: propylene derived from polyethylene, and both propylene and isobutylene derived from polypropylene. Both of these chemicals are in high demand; propylene is an important raw material for the chemical industry, while isobutylene is a frequently used monomer in many different polymers, including synthetic rubber and a gasoline additive.

Mixing It Up

Because plastics are often mixed at recycling centers, the researchers wanted to see what would happen if polypropylene and polyethylene underwent isomerizing ethenolysis together. The reaction was successful, converting the mixture into propylene and isobutylene, with slightly more propylene than isobutylene.

Mixtures also typically include contaminants in the form of additional plastics. So the team also wanted to see whether the reaction would still work if there were contaminants. They experimented with plastic objects that would otherwise be thrown away, including a centrifuge and a bread bag, both of which contained traces of other polymers besides polypropylene and polyethylene. The reaction yielded only slightly less propylene and isobutylene than it did with unadulterated versions of the polyolefins.

Another test involved introducing different plastics, such as PET and PVC, to polypropylene and polyethylene to see if that would make a difference. These did lower the yield significantly. If this approach is going to be successful, then all but the slightest traces of contaminants will have to be removed from polypropylene and polyethylene products before they are recycled.

While this recycling method sounds like it could prevent tons upon tons of waste, it will need to be scaled up enormously for this to happen. When the research team increased the scale of the experiment, it produced the same yield, which looks promising for the future. Still, we’ll need to build considerable infrastructure before this could make a dent in our plastic waste.

“We hope that the work described … will lead to practical methods for … [producing] new polymers,” the researchers said in the same study. “By doing so, the demand for production of these essential commodity chemicals starting from fossil carbon sources and the associated greenhouse gas emissions could be greatly reduced.”

38 notes

·

View notes

Text

Living plastics: A new solution for plastic degradation through synthetic biology

A study published in Nature Chemical Biology leverages the natural resilience of spores, which can endure extreme environmental conditions, by programming them to secrete plastic-degrading enzymes under specific circumstances. These spores are embedded into plastic matrices through standard plastic processing methods, such as high temperature, high pressure, or the use of organic solvents. In normal conditions, the spores remain dormant, ensuring the plastic's stable performance. However, when exposed to specific triggers like surface erosion or composting, the spores activate and initiate the degradation process, leading to the plastic's complete breakdown. The invention of plastics has improved our daily lives, but the massive production and improper disposal of plastic waste have made plastic pollution a major environmental issue. In 2016, Yoshida and team discovered a bacterium, Ideonella sakaiensis, in poly (ethylene terephthalate) (PET)-contaminated soil near a recycling facility in Japan. This bacterium can grow using PET as its main carbon source by producing two key enzymes: PETase and MHETase.

Read more.

42 notes

·

View notes

Text

Gas Alley Has Somehow Endured, While Its Notorious Neighborhood Faded Away

If you really want to visit Gas Alley today, you’ll have a bit of an adventure. Less than 300 feet in length, Gas Alley runs south from Longworth Hall to Mehring Way. It is paved with cobblestones interrupted by patches of gravel and surrounded by warehouses, a couple of light industrial sheds and a Duke Energy substation. There’s a street sign at the southern terminus.

No evidence remains of the little alley’s unsavory past. So disreputable was this byway that it lent its name to the entire surrounding neighborhood. The Cincinnati Times, in 1853, summed up Gas Alley’s reputation:

“This neighborhood, located in the Sixth Ward, is the most degraded in the city – rivaling, in some things, the noted Five Points of New York. Its dance-houses and grog-shops are numerous, and are the continual scenes of bloody fights, rows, and not unfrequently murders. The families who reside there, appear to be too fond of the degrading pleasures of the neighborhood; and drunken brawls, between man and wife, father and son, mother and daughter, are not uncommon in Gas Alley. Mothers and fathers are often found dead drunk, and their children ragged, starved and filthy, seen running around the streets, pilfering whatever they can lay their hands upon.”

Gas Alley got its name because it ran alongside the city’s gasworks. Before 1909, the Cincinnati Gas, Light & Coke Company manufactured its own gas, and resisted the use of natural gas. It was this so-called “town gas,” also known as “coal gas,” that was piped into Cincinnati homes. Town gas is manufactured by heating coal and the process results in a noxious and volatile mixture of hydrogen, carbon monoxide, methane and ethylene. By contrast, natural gas is mostly methane. Between 1841 and 1909, Cincinnati’s town gas flowed from a plant located adjacent to Gas Alley.

The Gas Alley neighborhood was centered around a compact triangle bordered by Gas Alley on the east, Second Street on the north and Front Street on the south. Today, Second Street is Pete Rose Way and Front Street is Mehring Way. It is inconceivable now, but there were once 45 tenement buildings plus the gasworks crammed into this little triangle. If you lived in Cincinnati prior to the Civil War, you knew to stay out of the place. A Cincinnati Gazette [2 June 1853] report is tragically typical:

“A man, named John Goller, while walking along the street near Gas alley, Tuesday evening, was attacked by a party of five or six men, who, with clubs and a large whip, beat him in a very severe manner, and left him on the sidewalk for dead.”

With no explanation about why they were fighting, as if no rationale, given the locality, was needed, the Gazette [19 February 1853] related another such incident:

“Thursday evening an affray took place in Gas alley, in which a female named Mary Finn raised a large bar of iron and struck a man over the head, cutting a frightful gash. She has been arrested.”

That summer, the regular disputes turned deadly, according to the Gazette [18 July 1853]:

“Gas Alley, a noted place for rowdyism, drunkenness and murders, was the scene of another bloody affray on Saturday night, which resulted in the murder of a man named Joseph Adams. We learn that a man named James Heffner and Adams got into a quarrel in regard to a trivial matter, when Adams picked up a brickbat and threw it at Heffner, striking him on the back. Heffner drew a pistol and fired back at Adams, the contents entering his forehead and lodging in his brain.”

Almost forty years later, Gas Alley was sadly maintaining its reputation. The Cincinnati Enquirer [1 March 1890] reported yet another melee in the storied neighborhood:

“Bowlders, clubs and clinched fists were the weapons used in a pitched battle last night between the police and a gang of rowdies in that classical thoroughfare, Gas alley.”

In that incident, a band of fifteen young toughs loitered along Front Street, spitting tobacco juice on passersby. Two police officers ordered the group to move along and were rebuffed, so the cops called in reinforcements from the Fourth District Station on Third Street and, according to the paper, “a general tumult ensued.”

Despite the frequency of violent crimes originating in Gas Alley, far too many news items related heart-breaking tales spawned by the oppressive poverty of the neighborhood. In his memoir, “Thirty-Five Years Among The Poor And The Public Institutions Of Cincinnati” (1887), Joseph Emery presents a common Gas Alley tragedy:

“One Sabbath evening, after a hard day's labor, during the severe frost in January, I was desired to visit a dying woman on Gas Alley, one of the most degraded sections of our city. On entering the dismal room, a dim candle revealed six or seven colored people, nearly intoxicated. On a scantily furnished bed lay the wife of the occupant, who appeared to be past medical aid, and had quite lost the power of speech. On proposing to read and pray, they consented. There was not a chair in the room, but an old box formed the only seat. The only window in the room was left open to let out the smoke, but it let in the strong odor from the Gas House and the sharp breath of winter. During prayer the dying woman wept, but spoke not one word. I left money with a friend, and an order for food on the Relief Union. I then gave a solemn warning to all to give up liquor, which was hurrying them all to perdition. Soon after my departure, and the other friends left, all these wretched people went off drinking, and in the morning the woman was found frozen to death! Her own husband had left her to die alone!”

Over the years, Cincinnati has created quite a few disreputable slums, from Bucktown to Rat Row to Sausage Row to Frogtown to Charcoal Alley. Each has exhibited a unique character. The Gas Alley community distinguished itself because its inhabitants were an incendiary admixture of Irish and African American, two tribes that more commonly segregated themselves into different parts of town. There is every indication that the Irish residents of Gas Alley were too poor to aspire to a hovel on Rat Row and the Black population could not afford to reside in Bucktown.

Despite repeated efforts by the city to vacate the little thoroughfare, Gas Alley has somehow endured. On a recent autumn afternoon, the cobblestones gave not a clue to their storied past of blood and tears. Perhaps Gas Alley needs a historic plaque of some sort. If so, it would appropriately be manufactured of tin rather than bronze.

17 notes

·

View notes

Text

MIT engineers make converting CO2 into useful products more practical

New Post has been published on https://sunalei.org/news/mit-engineers-make-converting-co2-into-useful-products-more-practical/

MIT engineers make converting CO2 into useful products more practical

As the world struggles to reduce greenhouse gas emissions, researchers are seeking practical, economical ways to capture carbon dioxide and convert it into useful products, such as transportation fuels, chemical feedstocks, or even building materials. But so far, such attempts have struggled to reach economic viability.

New research by engineers at MIT could lead to rapid improvements in a variety of electrochemical systems that are under development to convert carbon dioxide into a valuable commodity. The team developed a new design for the electrodes used in these systems, which increases the efficiency of the conversion process.

The findings are reported today in the journal Nature Communications, in a paper by MIT doctoral student Simon Rufer, professor of mechanical engineering Kripa Varanasi, and three others.

“The CO2 problem is a big challenge for our times, and we are using all kinds of levers to solve and address this problem,” Varanasi says. It will be essential to find practical ways of removing the gas, he says, either from sources such as power plant emissions, or straight out of the air or the oceans. But then, once the CO2 has been removed, it has to go somewhere.

A wide variety of systems have been developed for converting that captured gas into a useful chemical product, Varanasi says. “It’s not that we can’t do it — we can do it. But the question is how can we make this efficient? How can we make this cost-effective?”

In the new study, the team focused on the electrochemical conversion of CO2 to ethylene, a widely used chemical that can be made into a variety of plastics as well as fuels, and which today is made from petroleum. But the approach they developed could also be applied to producing other high-value chemical products as well, including methane, methanol, carbon monoxide, and others, the researchers say.

Currently, ethylene sells for about $1,000 per ton, so the goal is to be able to meet or beat that price. The electrochemical process that converts CO2 into ethylene involves a water-based solution and a catalyst material, which come into contact along with an electric current in a device called a gas diffusion electrode.

There are two competing characteristics of the gas diffusion electrode materials that affect their performance: They must be good electrical conductors so that the current that drives the process doesn’t get wasted through resistance heating, but they must also be “hydrophobic,” or water repelling, so the water-based electrolyte solution doesn’t leak through and interfere with the reactions taking place at the electrode surface.

Unfortunately, it’s a tradeoff. Improving the conductivity reduces the hydrophobicity, and vice versa. Varanasi and his team set out to see if they could find a way around that conflict, and after many months of trying, they did just that.

The solution, devised by Rufer and Varanasi, is elegant in its simplicity. They used a plastic material, PTFE (essentially Teflon), that has been known to have good hydrophobic properties. However, PTFE’s lack of conductivity means that electrons must travel through a very thin catalyst layer, leading to significant voltage drop with distance. To overcome this limitation, the researchers wove a series of conductive copper wires through the very thin sheet of the PTFE.

“This work really addressed this challenge, as we can now get both conductivity and hydrophobicity,” Varanasi says.

Research on potential carbon conversion systems tends to be done on very small, lab-scale samples, typically less than 1-inch (2.5-centimeter) squares. To demonstrate the potential for scaling up, Varanasi’s team produced a sheet 10 times larger in area and demonstrated its effective performance.

To get to that point, they had to do some basic tests that had apparently never been done before, running tests under identical conditions but using electrodes of different sizes to analyze the relationship between conductivity and electrode size. They found that conductivity dropped off dramatically with size, which would mean much more energy, and thus cost, would be needed to drive the reaction.

“That’s exactly what we would expect, but it was something that nobody had really dedicatedly investigated before,” Rufer says. In addition, the larger sizes produced more unwanted chemical byproducts besides the intended ethylene.

Real-world industrial applications would require electrodes that are perhaps 100 times larger than the lab versions, so adding the conductive wires will be necessary for making such systems practical, the researchers say. They also developed a model which captures the spatial variability in voltage and product distribution on electrodes due to ohmic losses. The model along with the experimental data they collected enabled them to calculate the optimal spacing for conductive wires to counteract the drop off in conductivity.

In effect, by weaving the wire through the material, the material is divided into smaller subsections determined by the spacing of the wires. “We split it into a bunch of little subsegments, each of which is effectively a smaller electrode,” Rufer says. “And as we’ve seen, small electrodes can work really well.”

Because the copper wire is so much more conductive than the PTFE material, it acts as a kind of superhighway for electrons passing through, bridging the areas where they are confined to the substrate and face greater resistance.

To demonstrate that their system is robust, the researchers ran a test electrode for 75 hours continuously, with little change in performance. Overall, Rufer says, their system “is the first PTFE-based electrode which has gone beyond the lab scale on the order of 5 centimeters or smaller. It’s the first work that has progressed into a much larger scale and has done so without sacrificing efficiency.”

The weaving process for incorporating the wire can be easily integrated into existing manufacturing processes, even in a large-scale roll-to-roll process, he adds.

“Our approach is very powerful because it doesn’t have anything to do with the actual catalyst being used,” Rufer says. “You can sew this micrometric copper wire into any gas diffusion electrode you want, independent of catalyst morphology or chemistry. So, this approach can be used to scale anybody’s electrode.”

“Given that we will need to process gigatons of CO2 annually to combat the CO2 challenge, we really need to think about solutions that can scale,” Varanasi says. “Starting with this mindset enables us to identify critical bottlenecks and develop innovative approaches that can make a meaningful impact in solving the problem. Our hierarchically conductive electrode is a result of such thinking.”

The research team included MIT graduate students Michael Nitzsche and Sanjay Garimella, as well as Jack Lake PhD ’23. The work was supported by Shell, through the MIT Energy Initiative.

0 notes

Text

MIT engineers make converting CO2 into useful products more practical

New Post has been published on https://thedigitalinsider.com/mit-engineers-make-converting-co2-into-useful-products-more-practical/

MIT engineers make converting CO2 into useful products more practical

As the world struggles to reduce greenhouse gas emissions, researchers are seeking practical, economical ways to capture carbon dioxide and convert it into useful products, such as transportation fuels, chemical feedstocks, or even building materials. But so far, such attempts have struggled to reach economic viability.

New research by engineers at MIT could lead to rapid improvements in a variety of electrochemical systems that are under development to convert carbon dioxide into a valuable commodity. The team developed a new design for the electrodes used in these systems, which increases the efficiency of the conversion process.

The findings are reported today in the journal Nature Communications, in a paper by MIT doctoral student Simon Rufer, professor of mechanical engineering Kripa Varanasi, and three others.

“The CO2 problem is a big challenge for our times, and we are using all kinds of levers to solve and address this problem,” Varanasi says. It will be essential to find practical ways of removing the gas, he says, either from sources such as power plant emissions, or straight out of the air or the oceans. But then, once the CO2 has been removed, it has to go somewhere.

A wide variety of systems have been developed for converting that captured gas into a useful chemical product, Varanasi says. “It’s not that we can’t do it — we can do it. But the question is how can we make this efficient? How can we make this cost-effective?”

In the new study, the team focused on the electrochemical conversion of CO2 to ethylene, a widely used chemical that can be made into a variety of plastics as well as fuels, and which today is made from petroleum. But the approach they developed could also be applied to producing other high-value chemical products as well, including methane, methanol, carbon monoxide, and others, the researchers say.

Currently, ethylene sells for about $1,000 per ton, so the goal is to be able to meet or beat that price. The electrochemical process that converts CO2 into ethylene involves a water-based solution and a catalyst material, which come into contact along with an electric current in a device called a gas diffusion electrode.

There are two competing characteristics of the gas diffusion electrode materials that affect their performance: They must be good electrical conductors so that the current that drives the process doesn’t get wasted through resistance heating, but they must also be “hydrophobic,” or water repelling, so the water-based electrolyte solution doesn’t leak through and interfere with the reactions taking place at the electrode surface.

Unfortunately, it’s a tradeoff. Improving the conductivity reduces the hydrophobicity, and vice versa. Varanasi and his team set out to see if they could find a way around that conflict, and after many months of trying, they did just that.

The solution, devised by Rufer and Varanasi, is elegant in its simplicity. They used a plastic material, PTFE (essentially Teflon), that has been known to have good hydrophobic properties. However, PTFE’s lack of conductivity means that electrons must travel through a very thin catalyst layer, leading to significant voltage drop with distance. To overcome this limitation, the researchers wove a series of conductive copper wires through the very thin sheet of the PTFE.

“This work really addressed this challenge, as we can now get both conductivity and hydrophobicity,” Varanasi says.

Research on potential carbon conversion systems tends to be done on very small, lab-scale samples, typically less than 1-inch (2.5-centimeter) squares. To demonstrate the potential for scaling up, Varanasi’s team produced a sheet 10 times larger in area and demonstrated its effective performance.

To get to that point, they had to do some basic tests that had apparently never been done before, running tests under identical conditions but using electrodes of different sizes to analyze the relationship between conductivity and electrode size. They found that conductivity dropped off dramatically with size, which would mean much more energy, and thus cost, would be needed to drive the reaction.

“That’s exactly what we would expect, but it was something that nobody had really dedicatedly investigated before,” Rufer says. In addition, the larger sizes produced more unwanted chemical byproducts besides the intended ethylene.

Real-world industrial applications would require electrodes that are perhaps 100 times larger than the lab versions, so adding the conductive wires will be necessary for making such systems practical, the researchers say. They also developed a model which captures the spatial variability in voltage and product distribution on electrodes due to ohmic losses. The model along with the experimental data they collected enabled them to calculate the optimal spacing for conductive wires to counteract the drop off in conductivity.

In effect, by weaving the wire through the material, the material is divided into smaller subsections determined by the spacing of the wires. “We split it into a bunch of little subsegments, each of which is effectively a smaller electrode,” Rufer says. “And as we’ve seen, small electrodes can work really well.”

Because the copper wire is so much more conductive than the PTFE material, it acts as a kind of superhighway for electrons passing through, bridging the areas where they are confined to the substrate and face greater resistance.

To demonstrate that their system is robust, the researchers ran a test electrode for 75 hours continuously, with little change in performance. Overall, Rufer says, their system “is the first PTFE-based electrode which has gone beyond the lab scale on the order of 5 centimeters or smaller. It’s the first work that has progressed into a much larger scale and has done so without sacrificing efficiency.”

The weaving process for incorporating the wire can be easily integrated into existing manufacturing processes, even in a large-scale roll-to-roll process, he adds.

“Our approach is very powerful because it doesn’t have anything to do with the actual catalyst being used,” Rufer says. “You can sew this micrometric copper wire into any gas diffusion electrode you want, independent of catalyst morphology or chemistry. So, this approach can be used to scale anybody’s electrode.”

“Given that we will need to process gigatons of CO2 annually to combat the CO2 challenge, we really need to think about solutions that can scale,” Varanasi says. “Starting with this mindset enables us to identify critical bottlenecks and develop innovative approaches that can make a meaningful impact in solving the problem. Our hierarchically conductive electrode is a result of such thinking.”

The research team included MIT graduate students Michael Nitzsche and Sanjay Garimella, as well as Jack Lake PhD ’23. The work was supported by Shell, through the MIT Energy Initiative.

#000#air#applications#approach#Building#Capture#carbon#Carbon dioxide#catalyst#challenge#change#chemical#chemistry#climate#CO2#communications#conductors#Conflict#data#Design#development#diffusion#economic#efficiency#electrochemical#electrode#electrodes#electrolyte#electrons#Emissions

0 notes

Text

Ethylene Market In-depth Analysis and Comprehensive Assessment Report 2024 to 2033

The ethylene market is a major segment of the petrochemical industry and plays a critical role in global manufacturing. Ethylene is one of the most widely used chemical compounds, serving as a primary building block for various essential materials, including polyethylene, ethylene oxide, and ethylene dichloride. These derivatives are extensively used in producing plastics, textiles, automotive components, packaging, construction materials, and pharmaceuticals. With demand spread across a diverse range of sectors, the ethylene market is a key player in global industrial development.

Market Overview and Size

The Global Ethylene Market is projected to reach approximately USD 304.6 Billion by 2033, increasing from USD 177.7 Billion in 2023, with a compound annual growth rate (CAGR) of 5.6% during the forecast period from 2023 to 2033. Growth in this market is primarily driven by the expanding consumer base for products made from ethylene derivatives and the growing demand for plastic and synthetic materials across multiple industries. The market is also heavily influenced by the price of crude oil and natural gas, as these are primary feedstocks for ethylene production.

Get Information About This Report: https://infinitymarketresearch.com/ethylene-market/1060

Key Drivers of the Ethylene Market

Growth in the Plastic and Packaging Industries A significant portion of ethylene is used to produce polyethylene, one of the most widely used plastics. Polyethylene is essential in manufacturing plastic bags, containers, and packaging materials, which are in constant demand due to the booming e-commerce and retail sectors. The growth in packaging requirements—driven by increased online shopping and a shift toward lightweight packaging in industries like food, beverages, and consumer goods—continues to be a major growth driver for the ethylene market.

Demand from Automotive and Construction Sectors Ethylene-derived materials like polypropylene, styrene, and polyvinyl chloride (PVC) are crucial in automotive and construction applications. In the automotive industry, lightweight materials are increasingly used to enhance fuel efficiency. In the construction industry, PVC pipes, fittings, and insulation materials are essential for both residential and commercial structures. With expanding infrastructure development in emerging markets, the demand from these industries is expected to fuel ethylene consumption in the coming years.

Advancements in Production Technologies Technological advancements in ethylene production have significantly improved production efficiency and reduced costs. Modern methods, such as cracking technology and catalytic processes, allow companies to convert naphtha and ethane into ethylene with greater energy efficiency and lower environmental impact. In addition, companies are investing in sustainable production technologies, such as bio-based ethylene, to reduce the industry’s carbon footprint and comply with increasing environmental regulations.

Regional Insights

Asia-Pacific The Asia-Pacific region dominates the ethylene market, with China, India, and Japan as major consumers. This region’s growth is driven by rapid industrialization, urbanization, and increasing consumer spending on goods made from ethylene derivatives. China, in particular, has seen a tremendous rise in demand due to its robust manufacturing sector, which includes automotive, electronics, and consumer goods industries. Additionally, Asia-Pacific is investing heavily in new ethylene production facilities to reduce reliance on imports and support local demand.

North America North America is a significant player in the ethylene market, largely due to the abundance of shale gas reserves in the United States. The shale gas boom has provided a low-cost feedstock (ethane) for ethylene production, allowing the U.S. to emerge as a global ethylene exporter. With the presence of advanced production technologies and investments in petrochemical infrastructure, North America is expected to maintain its influence in the global ethylene market.

Europe Europe’s ethylene market is more moderate in growth due to stringent environmental regulations and a high degree of market maturity. However, demand from the automotive and construction industries continues to drive moderate growth in ethylene consumption. Additionally, Europe is actively working on producing bio-based ethylene and recycling initiatives to address environmental concerns and reduce dependence on fossil fuels.

Challenges in the Ethylene Market

Environmental Concerns and Regulatory Challenges The ethylene industry faces increasing scrutiny over its environmental impact, as ethylene production is energy-intensive and generates considerable carbon emissions. Regulatory pressure is mounting on the industry to adopt cleaner, more sustainable production methods. As a result, companies are investing in carbon capture and storage (CCS) technologies and renewable feedstocks to minimize their environmental footprint.

Volatility in Raw Material Prices Ethylene production relies heavily on crude oil and natural gas as raw materials, making the market sensitive to fluctuations in their prices. Price volatility due to geopolitical tensions, trade policies, and supply-demand imbalances can impact production costs and profitability. To counter this, companies are diversifying feedstock sources and adopting flexible production technologies that can switch between different raw materials depending on cost and availability.

Competition from Alternative Materials The push for environmentally sustainable alternatives is driving research into bio-based and recycled plastics, which could potentially substitute petrochemical-based ethylene products. These alternative materials have gained popularity in industries seeking eco-friendly solutions, posing a potential challenge to the ethylene market’s growth.

Key Players:

o Chevron Phillips Chemical Company LLC

o China Petroleum & Chemical Corporation (Sinopec)

o Mitsui Chemicals Inc.

o LyondellBasell Industries N.V.

o Exxon Mobil Corporation

o Saudi Basic Industries Corporation

o Ineos Group Ltd

o The Dow Chemical Company

o Royal Dutch Shell plc

o LG Chem Ltd.

o Mitsui Chemicals Inc.

o Other Key Players

Get Free Sample Copy Of Report: https://infinitymarketresearch.com/request-sample/1060

Future Outlook and Opportunities

The ethylene market is expected to continue its growth trajectory, driven by demand from emerging markets and ongoing industrial applications. Companies are actively pursuing strategies to make the ethylene industry more sustainable, including investment in bio-based ethylene, recycling technologies, and energy-efficient production methods. Additionally, with growing global attention on sustainability, bio-based ethylene and renewable energy sources will likely play a larger role in the industry’s future.

Investments in research and development are expected to foster innovations that lower production costs, reduce environmental impact, and enhance the performance of ethylene derivatives. The expansion of industries such as packaging, automotive, and construction in emerging economies is also anticipated to provide long-term opportunities in the ethylene market.

Related Reports:

Glyceryl Triacetate Market Trends and Growth | Report 2033 : https://infinitymarketresearch.com/glyceryl-triacetate-market/1223

Diisopropyl Ether (DIPE) Market Trends, Growth | Report 2033: https://infinitymarketresearch.com/diisopropyl-ether-(dipe)-market/1243

Atomized Metal Powder Market Size, Growth, Trends, Report 2033: https://infinitymarketresearch.com/atomized-metal-powder-market/1250

Fire Resistant Tapes Market Size, Growth, Trends, Report 2033: https://infinitymarketresearch.com/fire-resistant-tapes-market/1281

Ceramic Additive Manufacturing Market Size, Growth, Report 2033: https://infinitymarketresearch.com/ceramic-additive-manufacturing-market/1280

About US:

We at Infinity Market Research hold expertise in providing up-to-date, authentic and reliable information across all the industry verticals. Our diverse database consists of information gathered from trusted and authorized data sources.

We take pride in offering high quality and comprehensive research solution to our clients. Our research solutions will help the clients in making an informed move and planning the business strategies. We strive to provide excellent and dedicated market research reports so that our clients can focus on growth and business development plans. We have domain-wise expert research team who work on client-specific custom projects. We understand the diverse requirements of our clients and keep our reports update based on the market scenario.

Contact US:

Pune, Maharashtra, India

Mail: [email protected]

Website: https://infinitymarketresearch.com/

#EthyleneMarket#Petrochemicals#SustainableManufacturing#PlasticsIndustry#IndustrialGrowth#EthyleneProduction#ChemicalIndustry#PackagingDemand#GlobalMarkets

0 notes

Text

EPDM Roofing: A Durable and Cost-Effective Solution

Choosing the right roofing material is crucial for ensuring the long-term protection and performance of any building. One option that has gained significant attention in recent years is EPDM roofing. Known for its durability, flexibility, and cost-effectiveness, EPDM roofing has become a popular choice for both residential and commercial properties. In this article, we’ll explore the benefits of EPDM roofing, how it compares to other materials like metal roofs, and why Trent Roofing & Cladding is the ideal choice for your next roofing project.

What is EPDM Roofing?

EPDM roofing stands for Ethylene Propylene Diene Monomer, a synthetic rubber membrane widely used in low-slope buildings. This single-ply roofing system has been around for decades and is well-known for its resilience, weather resistance, and long lifespan. Whether you are looking to install a new roof or replace an old one, EPDM roofing provides an effective solution for keeping your building safe from the elements.

Key Features of EPDM Roofing

Durability: EPDM roofing is known for its ability to withstand extreme weather conditions, including intense heat, heavy rainfall, and even snow. It has a high resistance to UV rays, ozone, and oxidation, which helps extend its lifespan.

Flexibility: One of the standout features of EPDM roofing is its flexibility. It can stretch and adapt to different temperatures, making it ideal for regions with fluctuating weather conditions. This flexibility also makes it resistant to cracking and tearing.

Easy Installation and Maintenance: EPDM roofing is relatively easy to install, especially when handled by professional contractors like Trent Roofing & Cladding. The material comes in large sheets, reducing the number of seams and minimizing potential leak points. Additionally, its maintenance is simple and cost-effective, requiring occasional inspections and minor repairs.

Cost-Effective: Compared to other roofing materials, EPDM roofing is an affordable option. Its long lifespan and low maintenance costs make it a cost-effective investment for building owners.

Benefits of EPDM Roofing

1. Longevity and Durability

One of the main reasons building owners choose EPDM roofing is its long lifespan. With proper installation and maintenance, EPDM roofs can last up to 30 years or more. The material is resistant to weathering, UV exposure, and extreme temperatures, which ensures its durability in various climates. Whether you live in a hot, sunny area or a cold, snowy region, EPDM roofing can stand the test of time.

2. Environmental Benefits

If you're looking for an environmentally friendly roofing option, EPDM roofing is an excellent choice. EPDM membranes are made from recycled materials and are 100% recyclable at the end of their lifespan. Additionally, EPDM roofing can help improve the energy efficiency of your building by reflecting heat in hot climates and retaining warmth in cooler regions. This contributes to lower energy bills and a reduced carbon footprint.

3. Fire Resistance

Safety is a top priority when selecting a roofing material. EPDM roofing is fire-resistant, which adds an extra layer of protection to your building. This is particularly important for commercial properties where fire hazards may be more common. EPDM roofing can help slow the spread of fire and minimize potential damage to your property.

4. Compatibility with Solar Panels

For building owners looking to embrace renewable energy, EPDM roofing is an excellent choice. Its flat, smooth surface makes it easy to install solar panels, allowing you to take advantage of clean, renewable energy. The durability of EPDM roofing ensures that it can support the weight of solar panels without compromising the integrity of the roof.

Comparing EPDM Roofing with Metal Roofs

While EPDM roofing offers many advantages, it’s important to compare it to other popular roofing materials such as metal roofs. Both EPDM roofing and metal roofs have unique benefits that cater to different building needs.

Metal Roofs

Metal roofs are known for their strength, longevity, and sleek appearance. They are typically made from materials like steel, aluminum, or copper, which provide excellent protection against the elements. Metal roofs can last up to 50 years or more, making them a long-term investment for building owners. Additionally, metal roofs are fire-resistant and highly durable, making them an attractive option for those looking for a robust roofing solution.

Advantages of Metal Roofs

Longevity: As mentioned, metal roofs can last up to 50 years or more with proper maintenance. This makes them one of the longest-lasting roofing materials available.

Energy Efficiency: Metal roofs are highly reflective, helping to reduce heat absorption and lower cooling costs during the summer. Like EPDM roofing, they contribute to energy efficiency.

Durability: Metal roofs are highly resistant to weather damage, including high winds, hail, and heavy snow. They are also resistant to mold, mildew, and rot, which can be common issues with other roofing materials.

Conclusion: EPDM vs. Metal Roofs

When deciding between EPDM roofing and metal roofs, it’s essential to consider your budget, building type, and climate. EPDM roofing is a more affordable option with excellent flexibility and energy efficiency, making it ideal for flat or low-slope roofs. On the other hand, metal roofs are a long-term investment, offering superior durability and a modern appearance. For professional installation and expert advice, Trent Roofing & Cladding can help you choose the best roofing solution for your needs.

Why Choose Trent Roofing & Cladding for EPDM Roofing?

At Trent Roofing & Cladding, we specialize in providing high-quality roofing solutions tailored to your specific needs. Whether you’re interested in EPDM roofing for its flexibility and durability or a metal roof for its strength and longevity, our team of experts has the experience and expertise to ensure a successful installation.

Professional Installation

Proper installation is key to maximizing the benefits of your roofing system. Our skilled contractors are trained in installing EPDM roofing and metal roofs, ensuring a seamless and professional finish. We use only the highest-quality materials, ensuring that your roof provides long-lasting protection against the elements.

Customized Solutions

Every building is unique, which is why we offer customized roofing solutions tailored to your specific requirements. Whether you’re working on a residential, commercial, or industrial project, we’ll work with you to determine the best roofing material for your building.

Commitment to Quality

At Trent Roofing & Cladding, we are committed to delivering top-quality results that stand the test of time. Our dedication to excellence ensures that your roofing system not only looks great but also provides reliable protection for years to come.

Final Thoughts

When it comes to roofing, choosing the right material is essential for ensuring the longevity and performance of your building. EPDM roofing offers a durable, flexible, and cost-effective solution for low-slope buildings, making it a popular choice for both residential and commercial properties. With its ability to withstand extreme weather conditions, improve energy efficiency, and support renewable energy systems, EPDM roofing is a versatile and environmentally-friendly option.

For those considering other roofing materials, metal roofs provide a strong and long-lasting alternative. While they may come with a higher upfront cost, their durability and sleek design make them a worthwhile investment.

Whether you’re interested in EPDM roofing or a metal roof, Trent Roofing & Cladding has the expertise and experience to deliver exceptional results. Contact us today to learn more about our roofing services and how we can help you protect your property for years to come.

1 note

·

View note

Text

Poly Vinyl Chloride (PVC) Prices | Pricing | News | Database | Chart | Forecast

Polyvinyl chloride, commonly referred to as PVC, is one of the most widely used synthetic plastic polymers in the world. The pricing dynamics of PVC are influenced by a wide range of factors, from global supply and demand imbalances to fluctuations in raw material costs, particularly those of ethylene and chlorine. As a versatile material used in applications ranging from construction and infrastructure to healthcare and consumer goods, the price of PVC is often reflective of macroeconomic trends, shifts in industry needs, and geopolitical influences that may disrupt supply chains.

The raw materials that make up PVC, primarily ethylene, are often derived from petroleum or natural gas. Thus, fluctuations in crude oil and natural gas prices play a significant role in PVC pricing. When oil prices rise, the cost of ethylene can increase, leading to a subsequent rise in PVC prices. Similarly, any disruptions in the supply of chlorine, often tied to chlor-alkali production, can impact the price of PVC resin. Market trends in key producing regions such as the United States, China, and Europe also shape global price movements. For example, the United States, being a major producer and exporter of PVC, often experiences shifts due to weather-related factors such as hurricanes that can temporarily halt production and raise prices globally.

Get Real Time Prices for Poly Vinyl Chloride (PVC): https://www.chemanalyst.com/Pricing-data/poly-vinyl-chloride-5

Global trade policies and tariffs are also critical factors in determining PVC prices. Restrictions on imports or exports, particularly in key markets, can alter supply-demand balances and lead to regional price variations. For instance, China's domestic demand and capacity expansion have far-reaching effects on the global market. In some cases, anti-dumping duties and trade restrictions imposed by one country on another can create regional price discrepancies. Meanwhile, shifts in trade relationships can open or close access to raw materials and influence the cost structures for PVC manufacturers.

Environmental regulations and sustainability trends also play an increasingly important role in PVC pricing. As regulatory scrutiny over the environmental impacts of plastics grows, manufacturers are facing pressure to adopt greener technologies, improve recyclability, and reduce carbon emissions during production. While these measures may lead to higher production costs in the short term, they are essential for the industry's long-term viability. Additionally, consumer and industrial preferences for sustainable materials may affect demand patterns, with potential implications for pricing trends. Recycling initiatives, bio-based alternatives, and circular economy practices could introduce further cost considerations that ripple through the supply chain.

Currency exchange rates are another variable that influences PVC prices, particularly for markets that are heavily dependent on imports or exports. When a country's currency weakens against the US dollar, for example, the cost of importing PVC resin can rise, driving up local prices. Conversely, a strong domestic currency can make exports less competitive. Currency fluctuations can also introduce volatility in regions with unstable economic conditions, further complicating pricing strategies for both producers and buyers.

Technological advancements in the manufacturing of PVC, including improvements in polymerization techniques and additive formulations, have contributed to shifts in production efficiency and cost structure. These innovations can lead to cost savings and potentially lower prices over the long run, but initial investments and adoption rates can vary. Meanwhile, competition among major PVC producers drives pricing strategies aimed at capturing market share, often through promotional pricing or value-added offerings that may not immediately reflect changes in raw material costs.

Logistical factors such as transportation costs, availability of shipping containers, port congestion, and customs clearance times also affect the price of PVC. During periods of high demand or supply chain disruptions, logistical constraints can lead to increased costs, as seen in recent years when global shipping bottlenecks caused freight rates to surge. The cost of transporting raw materials and finished PVC products contributes directly to pricing, particularly for international trade routes where margins may be thin.

The global PVC market is highly interconnected, meaning that regional events can have far-reaching implications. Natural disasters, geopolitical tensions, and unexpected shutdowns or maintenance at production facilities can create supply shocks that ripple through the market. The availability and pricing of alternative materials can also influence demand for PVC; for example, if another material becomes prohibitively expensive or scarce, buyers may switch to PVC, thereby increasing demand and driving up prices.

Finally, long-term forecasts for PVC pricing are inherently uncertain due to the complex and evolving nature of the market. Analysts must weigh myriad factors such as global economic conditions, environmental regulations, technological innovations, and shifts in end-user demand. However, industry consensus often points to continued growth driven by infrastructure investments, especially in developing countries where urbanization and industrialization are rapidly expanding. As the world transitions to more sustainable and resilient supply chains, the PVC market will likely see significant evolution, with price trends reflecting this dynamic interplay of market forces and regulatory pressures.

Our Related News for Poly Vinyl Chloride (PVC) : https://www.chemanalyst.com/NewsAndDeals/NewsDetails/pvc-prices-rise-in-october-as-market-sentiment-improves-in-asia-and-the-us-30628

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#PVC Price#PVC Prices#PVC Monitor#Poly Vinyl Chloride#Poly Vinyl Chloride Price#Poly Vinyl Chloride Prices

0 notes

Text

Ethylene Absorber Market –By Product, By Chemicals,By Application, By End User & Industry Forecast, 2024–2030

Ethylene Absorber Market Overview:

The Ethylene Absorber Market size is estimated to reach $35.7 billion by 2030, growing at a CAGR of 18% over the forecast period 2024–2030. The Ethylene Absorber market plays a vital role in preserving fresh produce and perishable goods. It involves the development and deployment of technologies and products that control and reduce ethylene gas concentrations in storage, transportation, and retail environments.

Consumers and businesses are increasingly conscious of environmental sustainability. Ethylene absorbers are being adopted as eco-friendly solutions that help reduce food waste by extending produce life, thereby reducing the carbon footprint associated with food production and distribution. As the world becomes more connected, the need for products like ethylene absorbers that can preserve produce during long-distance transportation and storage has increased. Continuous innovation in ethylene absorber technology makes these solutions more effective, reliable, and affordable, further driving market growth.

The crisis in Ukraine and its neighboring regions has disrupted the supply chain for materials used in the production of ethylene absorbers. This has led to price fluctuations and potential shortages. Economic repercussions from the crisis, such as changes in currency exchange rates and trade sanctions, have influenced the cost of ethylene absorber production and affect pricing strategies.

Sample Report :

● South American Region Expected to Witness the Highest Growth Over the Forecast Period 2024–2030 :

The South American region is anticipated to experience the highest growth during the forecast period from 2024 to 2030, with a Compound Annual Growth Rate (CAGR) of 22%. Demand for ethylene absorbers is rising as South American nations place a greater emphasis on the growth of their agricultural industries. A natural plant hormone called ethylene is essential to the ripening of fruits and vegetables. Producers and retailers in the agricultural industry are realizing how crucial it is to use ethylene absorbers to keep produce fresher for longer periods while it is being transported and stored. This development is consistent with South America’s aim to improve agricultural productivity, which has led to a notable growth in the market for ethylene absorbers in the area.

Ethylene Absorbers Filters Registers the Fastest Growth :

Ethylene absorber filters are designed to efficiently and effectively remove ethylene gas from storage facilities, shipping containers, and refrigeration units. They provide a high level of control over ethylene levels, preventing premature ripening and decay of perishable products. It aligns with the growing emphasis on environmental sustainability. They help reduce food waste, which is not only cost-effective but also eco-friendly, making them an attractive option for businesses aiming to minimize their carbon footprint. The increasing demand for fresh produce year-round has intensified the need for efficient ethylene control solutions. Ethylene absorber filters play a crucial role in ensuring that consumers have access to high-quality, fresh fruits and vegetables, regardless of the season.

Inquiry Before Buying:

● Food Processing is the Largest Segment :

Food processing and packaging companies handle a substantial volume of perishable goods, including fruits, vegetables, and other food products. These companies process, package, and distribute these goods to a wide range of consumers and businesses. Food processing companies face the challenge of minimizing food waste during processing and packaging. Ethylene absorbers enable them to reduce spoilage and waste, leading to cost savings and increased profitability. Food processing and packaging companies benefit from the continuous technological advancements in ethylene absorber solutions. New materials and designs make these solutions even more effective and efficient, enhancing the quality of their products.

● Growing Demand for Fresh Produce :

The increasing consumer preference for fresh and healthy produce has been a significant driver for the Ethylene Absorber Market. Consumers are now more conscious of their dietary choices and are seeking fresh, high-quality fruits and vegetables year-round. This trend has propelled the need for ethylene absorbers, which extend the shelf life of perishables by reducing ethylene gas levels. As a result, the market has experienced consistent growth as consumers demand access to fresh produce regardless of the season.

Schedule a Call :

● Sustainability and Environmental Concerns :

Sustainability is a central concern for both businesses and consumers. Ethylene absorbers are seen as eco-friendly solutions that help reduce food waste, lower carbon footprints, and minimize the need for excessive packaging. The market has expanded as ethylene absorbers align with sustainability goals. Businesses are adopting these solutions to meet eco-conscious consumer demands while reducing their environmental impact.

Buy Now :

● Supply Chain Disruptions :

The Ethylene Absorber Market can be heavily reliant on supply chains for raw materials. Any disruption, such as those caused by global events or geopolitical tensions, can impact production and lead to price fluctuations. Supply chain disruptions can affect the market’s stability, causing delays in production and increased costs, which can be passed on to consumers. Companies need to diversify their sources and enhance supply chain resilience to mitigate these challenges.

For more information Ethylene Absorber Market click here

#ethyleneabsorber#foodpackaging#sustainablepackaging#reducefoodwaste#supplychaininnovation#foodtechnology#postharvestmanagement#freshproduce#foodsafety

0 notes

Text

Prussian blue analogs unlock affordable, long-lasting lithium-ion batteries

Prussian blue (PB), a well-known pigment used to dye jeans, has been recognized as an emerging material for next-generation batteries. A team of researchers, led by Professor Hyun-Wook Lee in the School of Energy and Chemical Engineering at UNIST has made a significant breakthrough in the development of low-cost, high-performance lithium-ion batteries (LIBs) using PB, leading to significantly reduced battery prices. The study, published in Nano Letters, demonstrates a new electrolyte system that overcomes the limitations of PB's slow kinetics and valence state inactivation, enabling stable and efficient battery operation. In this study, the research team developed a novel polymeric cathode electrolyte interphase (CEI) layer through a ring-opening reaction of ethylene carbonate triggered by OH– radicals from structural water. This innovative approach significantly improves the electrochemical kinetics in organic electrolytes, achieving a specific capacity of 125 mAh/g with a stable lifetime over 500 cycles.

Read more.

16 notes

·

View notes

Text

0 notes

Text

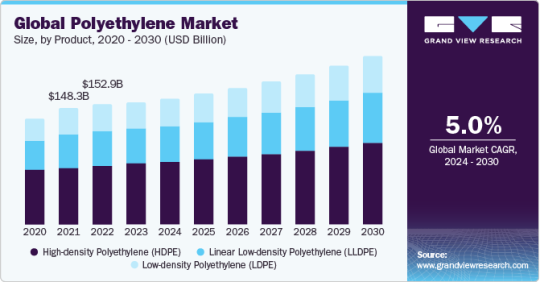

Polyethylene Market Size To Reach USD 213.77 Billion By 2030

Polyethylene Market Growth & Trends

The global polyethylene market size is anticipated to reach USD 213.77 billion by 2030, growing at a CAGR of 5.0% during the forecast period, according to a new report by Grand View Research, Inc. The market growth is driven by the increasing consumption of plastics in the automotive, medical, construction, and electrical & electronics industries. Moreover, the increasing demand for lightweight materials in the automotive industry contributes to industry growth. Polyethylene (PE) is commonly used for manufacturing lightweight plastics, films, and foams used in vehicles.

The emphasis of the automotive industry on enhancing the fuel efficiency of vehicles by reducing their weight leads to the adoption of PE in this industry. As recycling technologies advance, the PE market adapts to integrate more recycled content into its products, contributing to a more circular and resource-efficient approach. Government policies and regulations supporting sustainable practices further bolster the demand for recycled PE. The circular economy encourages the collection, separation, and reprocessing of used PE products, diverting them from landfills.

One of the major challenges faced by the market includes fluctuations in raw material prices. The global crude oil prices have witnessed severe fluctuations in the past few years. Social disruption in key crude oil-producing regions, such as Venezuela, Libya, Iran, Nigeria, and Iraq has hampered crude oil supply, generating inelasticity in the supply-demand balance. These factors are short-lived in the market causing immediate fall and rise in prices, thus impacting market growth.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/polyethylene-pe-market

Key Polyethylene Company Insights

Key companies are adopting several organic and inorganic growth strategies, such as new product development, mergers & acquisitions, and joint ventures, to maintain and expand their market share.

In November 2023, Dow announced an investment in the Fort Saskatchewan Path2Zero project in Alberta, Canada, with an investment of USD 6.5 billion, as part of the company's goal to achieve carbon neutrality by 2050. The project involves the construction of a new ethylene plant and expanding polyethylene capacity by 2 million metric tons annually. The construction is scheduled to commence in 2024, and the increased capacity is set to be implemented in stages, with the initial phase anticipated to begin in 2027

In October 2023, Borealis AG and TotalEnergies SE announced plans to construct a USD 1.4 billion Borstar PE unit within their Baystar joint venture. This PE unit, boasting a capacity of 625,000 metric tons annually, marks a significant increase, doubling the current production capabilities at the Baystar site including two existing PE production units

In August 2023, Dow partnered with Mengniu, a dairy company, to launch a PE yogurt pouch, specifically designed for recyclability. This joint effort signifies a significant step for both companies in reinforcing their dedication to promoting a circular economy in China. The partnership with Mengniu enables both brands to take the lead in pioneering recyclable all-PE dairy packaging in the Chinese market.

Polyethylene Market Report Highlights

High-density Polyethylene (HDPE) dominated the product segment with more than 49.0% share in 2023. The demand for efficient and long-lasting solutions in water infrastructure and agriculture enhances the growth prospects of the HDPE segment

The Linear Low-density Polyethylene (LLDPE) type segment is expected to grow at the fastest CAGR of 5.5% over the forecast period

The bottles & containers application segment held a substantial market share in 2023. The sustainability trend in the packaging industry contributes to the growth of this segment

The use of recyclable materials is growing due to environmental concerns. The recyclability and compatibility of PE with recycling processes are essential for eco-conscious industries and consumers

Asia Pacific dominated the global market in 2023. The growing manufacturing industry in Asia Pacific is anticipated to drive the demand for PE

In October 2023, Borealis AG and TotalEnergies SE announced plans to construct a USD 1.4 billion Borstar PE unit within their Baystar joint venture. This PE unit, boasting a capacity of 625,000 metric tons annually, marks a significant increase, doubling the current production capabilities at the Baystar site including two existing PE production units

Regional Insights

The North America Polyethylene Market accounted for a significant revenue share of 19.2% in 2023. The shale gas boom in North America has transformed the regional PE market. The abundant and easy availability of cost-effective feedstocks derived from shale gas, particularly ethane, has given PE producers, based in North America, a significant competitive advantage.

U.S. Polyethylene Market Trends

The Polyethylene Market in the U.S.is expected to grow over the forecast period. The U.S. energy landscape, specifically the abundant availability of shale gas, is a critical driver for the PE market growth in the country. Shale gas serves as a primary feedstock for ethylene production, which is a key building block for PE. The accessibility and the cost competitiveness of shale gas contribute to the expansion of ethylene production capacities in the U.S., thereby supporting market growth.

Asia Pacific Polyethylene Market Trends

The Asia Pacific Polyethylene Market dominated the global industry in 2023 with a share of over 50.3%. Asia Pacific is a diverse market for PE owing to the growing automotive and construction industries in the region that are key consumers of this material. The growing manufacturing industry in Asia Pacific is anticipated to drive the requirement for PE.

The Polyethylene Market in China held a significant share in the Asia Pacific region. The market is anticipated to register a CAGR of 5.3% over the forecast period. Government initiatives for infrastructure development projects are driving market growth in China. The ambitious infrastructure development plans of the country, including the Belt and Road Initiative, stimulate the demand for PE in construction and related activities.

Polyethylene Market Segmentation

Grand View Research has segmented the global polyethylene market on the basis of product, application, end-use, and region:

PE Product Outlook (Volume, Kilotons, Revenue; USD Million, 2018 - 2030)

Low-density Polyethylene (LDPE)

High-density Polyethylene (HDPE)

Linear Low-density Polyethylene (LLDPE)

PE Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Bottles & Containers

Films & Sheets

Bags & Sacks

Pipes & Fittings

Other Applications

PE End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Packaging

Construction

Automotive

Agriculture

Consumer Electronics

Other End-uses

PE Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

Europe

Asia Pacific

Central & South America

Middle East & Africa

List of Key Players in the Polyethylene Market

BASF SE

Borealis AG

Braskem

Dow

Exxon Mobil Corporation

Formosa Plastics

INEOS Group

LG Chem

LyondellBasell Industries Holdings B.V.

Mitsubishi Chemical Corporation

MOL Group

SABIC

China Petrochemical Corporation (Sinopec)

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/polyethylene-pe-market

#Polyethylene Market#Polyethylene Market Size#Polyethylene Market Share#Polyethylene Market Trends#Polyethylene Market Growth

0 notes

Text

Polyvinyl Chloride (PVC) Market is in trends by growing construction activities